Table of Contents

ToggleUnleashing the Potential of EPDM Pads in Landscape Design

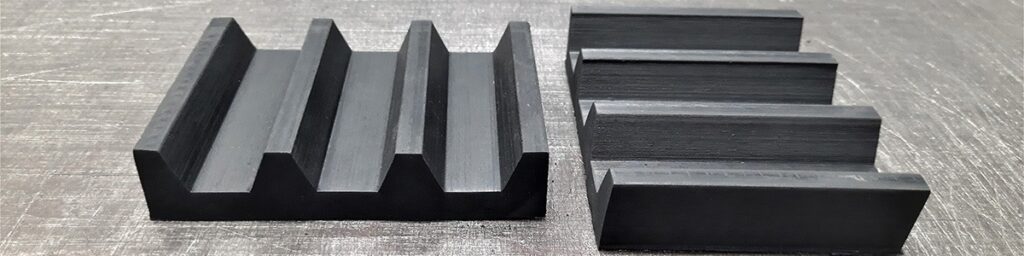

RE Wall Pads, also as Rubber Pads or EPDM Elastomeric Pads, are strategically placed between the slabs on RE (Reinforced Earth Wall) walls to prevent direct concrete-to-concrete contact. These pads serve several critical functions

Gap Maintenance: They help maintain the necessary gap in RE walls.

Vibration Absorption: By absorbing vibrations, they reduce the impact on the bridge, thus preventing structural damage.

Crack Prevention: Their use helps in avoiding cracks in the structure, ensuring long-term durability and integrity.

With these features, EPDM Elastomeric Pads play a vital role in enhancing the quality and longevity of construction projects.

Deevin’s EPDM Pads for Road Over Bridges

Deevin presents EPDM pads specifically designed for Road Over Bridges, featuring a customized assembly structure that ensures a secure connection with the groove of the mouth. These pads are equipped with an internal reinforcement plate, providing the necessary support to withstand the load of multiple vehicles while maintaining vertical rigidity. The unique design of the rubber plate indentation effectively prevents telescopic joints from swelling when compressed, thanks to the incompressibility of the rubber.

Benefits:

Excellent Anti-Ageing Properties: Ensures longevity and reliability over time.

High Compression Set Properties: Guarantees durability and optimal performance.

Low Replacement Costs: Minimizes maintenance expenses.

Wide Range: Available in various sizes and specifications.

Customization Options: Personalized approaches to fulfill certain project demands.

EPDM Expansion Joint: Reliable Solutions for Structural Integrity

The EPDM expansion joint is meticulously designed and crafted to handle the expansion, contraction, and vibration caused by temperature changes in roads, bridges, and similar structures. This expansion joint ensures the cohesion of different structural parts, allowing them to move safely during ground settlement or seismic activities. Deevin’s expansion joint profiles are essential for transferring forces from the superstructure to the substructure in bridge joints and comparable applications.

With variations in temperature, all building materials expand and compress. This expansion and contraction are quantified by a material’s coefficient of expansion. As temperatures rise, materials expand, and as temperatures fall, they contract. Therefore, expansion joints are crucial for absorbing these stresses and maintaining structural integrity.

Deevin produces expansion joint profiles that are not only easy to install but also highly durable. These profiles are typically installed on floors and sealed with a specialized adhesive.

Features

Outstanding Anti-Ageing Properties: Ensures the joints remain functional and effective over time.

High Compression Set Characteristics: Provides long-lasting durability and reliability.

Low Maintenance Costs: Reduces the need for frequent replacements.

Extensive Range of Tools: Offers a significant advantage to end users

Wide Variety of Options: Available in numerous sizes and specifications.

Customization Possibilities: Tailored to meet specific project needs.

EPDM rubber pad offers numerous advantages that make it a preferred choice for various applications, along with a few drawbacks that need consideration. Understanding both aspects is crucial before selecting EPDM for your specific use.

Advantages:

EPDM exhibits exceptional durability, flexibility, and resistance to UV exposure, ozone, aging, weathering, acids, and various chemicals, making it highly versatile. Its superior water resistance further adds to its appeal for outdoor applications. Unlike many other rubber types, EPDM does not fade or discolor (bloom) when exposed to environmental factors, ensuring long-lasting aesthetics. With proper maintenance, EPDM can endure for decades.

Another key advantage is EPDM’s wide temperature operating range, spanning from -60°F (-51°C) to 350°F (177°C). It maintains structural integrity even under cycling temperature conditions and is suitable for injection, compression, or transfer molding processes.

Disadvantages:

While EPDM excels in extreme temperatures and offers robust performance, it has limitations. It lacks good flame resistance and is susceptible to deterioration when exposed to mineral oils or petroleum oils over extended periods. Establishing a strong rubber-to-metal bond with EPDM can also be challenging.

Overall, while EPDM is among the top rubber polymers with impressive properties, its limitations, such as poor flame resistance and susceptibility to certain oils, should be carefully evaluated based on the intended application.

Common Applications of EPDM Rubber

EPDM rubber, renowned for its durability and resilience to environmental factors, finds widespread use across various industries due to its versatile properties. Some common applications of EPDM include:

- :Automotive Sector: EPDM pad serves in numerous automotive components such as seals for doors and windows, brake system elements, bumpers, windshield wipers, and various hoses and tubes, showcasing its durability and resistance to weathering.

- Locomotive Industry: In locomotives, EPDM is utilized for fabricating flexible connectors. Its flexibility, along with resistance to temperature extremes, ozone, and weathering, ensures longevity and reliable performance.

- Construction Field: EPDM plays a crucial role in construction applications, including roofing materials, sealants, garage door seals, and pool liners. Its ability to withstand harsh weather conditions makes it an ideal choice for outdoor construction projects.

- Industrial Applications: EPDM is widely used in industrial settings for water gaskets, O-rings, grommets, electrical insulation, and weather stripping, owing to its excellent sealing properties and resistance to chemicals.

These diverse applications underscore the versatility and utility of EPDM rubber across multiple industries, making it a preferred material for various demanding environments and applications.

Why Choose Deevin’s EPDM Rubber Surfacing for Next Project ?

When it comes to selecting the optimal solution for the next construction project. Deevin’s EPDM rubber surfacing stands out as an exceptional choice. Whether it’s for the automotive sector, locomotive industry, construction field, or industrial applications, EPDM rubber surfacing offers a range of benefits that make it an ideal option.

Here’s why you should consider Deevin’s EPDM rubber surfacing

- Versatile Solution: Tailored for automotive, locomotive, construction, and industrial needs.

- Durable & Safe: Withstand heavy machinery, high foot traffic, and harsh environmental conditions without compromising on quality or appearance.

- Customizable: Versatile design choices to suit specific industry needs.

- Eco-Friendly: Made from sustainable materials, contributing to environmental responsibility.

- Cost-Effective & Low Maintenance: Long-lasting durability translates to savings over time and reduced upkeep costs.

- Professional Installation: Expert services ensure quality and compliance standards.

Summing Up:

Deevin’s EPDM rubber surfacing emerges as a standout option. Designed to meet the rigorous demands of industries like automotive, locomotive, construction, and industrial sectors, Deevin’s EPDM rubber surfacing offers durability, and safety. Its ability to withstand heavy machinery, provide a safe working environment, and offer a range of design options while remaining low maintenance and environmentally responsible makes it a cost-effective and reliable choice. With Deevin’s expert installation support ensuring quality and compliance, opting for their EPDM rubber pad ensures a seamless blend of functionality, and sustainability for next construction endeavor.